Customer Stories

Inspiring stories: discover how our customers modernize their companies. From this page, you can access the description of the main projects made by Tattile and Chromasens.

Finding the suitable industrial PC for web inspection through conducting a product test

With its 100 employees the Italian specialist in the production of cycle measurement, control and automation systems Electronic Systems has made itself a name in the world of automation. Based in Momo in the province of Novara the company equips about 90 percent of the rubber plants existing in

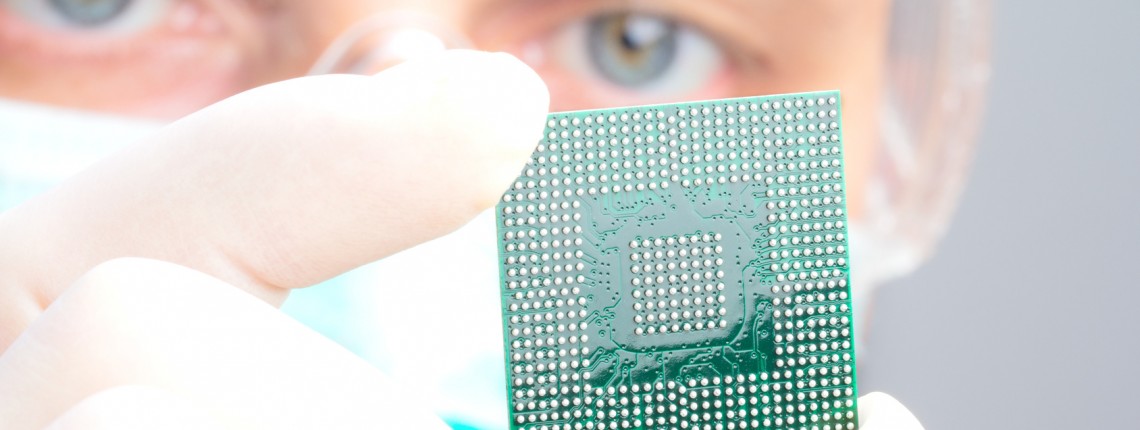

3D machine vision opens up new perspectives for AOI (Automated Optical Inspection)

A new dimension of quality control Miniaturisation in the field of semiconductor technology proceeds unimpeded. The development of increasingly smaller components and integrated circuits requires not only extremely precise production processes, but also new, innovative methods of quality control. The use of high-resolution 3D line scan cameras is one

3D image capturing system for on-track train inspection

In view of ever more complex railway networks and increasingly shorter cycles, the assurance of a fault-free function of railway vehicles is the top priority of railway operators. The implementation of new measuring methods such as high-precision 3D image capturing systems offers new strategies for innovative maintenance concepts. For

Novuslight: Publication of case study with Qualimatest

Read this article at Novuslight.com Based in Geneva in the east of Switzerland, Qualimatest is a machine vision integratorspecialized in optical quality control serving many industries where precision and quality assurance is of utmost importance. A key customer branch for Qualimatest is the medical sector. Here, Zubler Handling is one of the long-term customers that rely on the machine

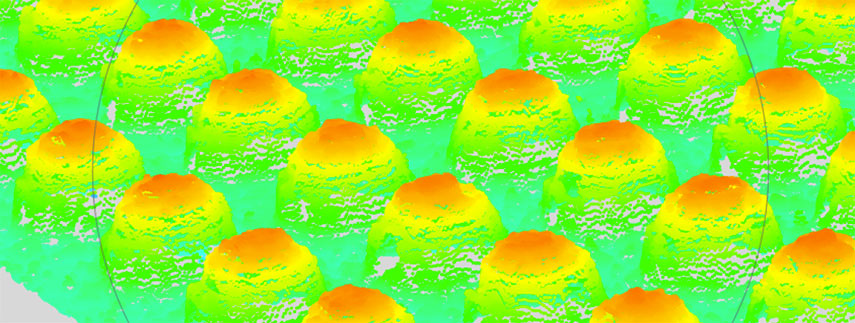

3DPIXA wave for BGA inspection

One BGA often consist of hundreds of single solder balls. To ensure the functionality of the electrical components, it is necessary that every single solder ball lead to a solid solder connection. The only way to ensure this is a one hundred percent inspection, where each solder ball must