Read this article at Novuslight.com

Based in Geneva in the east of Switzerland, Qualimatest is a machine vision integratorspecialized in optical quality control serving many industries where precision and quality assurance is of utmost importance. A key customer branch for Qualimatest is the medical sector. Here, Zubler Handling is one of the long-term customers that rely on the machine vision integration competence of Qualimatest. In the western part at the other end of Switzerland Zubler manufactures fully automatic production and packaging lines of pipettes for the world market which are used in the medical industry for assays with liquids in small volumes.

To ensure the sample accuracy, pipette tips must have a perfect geometry and surface finish. Therefore, integrated into the production line and right after the pipettes are ejected from the injection molding machines they are placed into standard racks of 96 pipettes per rack and visually inspected by the Qualimatest QMTSort-Tip vision system.

To ensure the sample accuracy, pipette tips must have a perfect geometry and surface finish. Therefore, integrated into the production line and right after the pipettes are ejected from the injection molding machines they are placed into standard racks of 96 pipettes per rack and visually inspected by the Qualimatest QMTSort-Tip vision system.

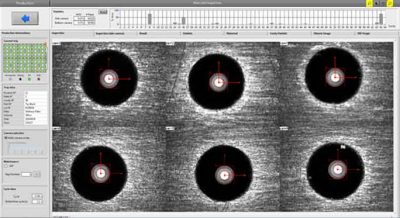

The main requirements on the vision based quality control system are to be fast and precise: within four seconds the vision system has to scan all 96 pipettes on a rack, measuring the inner and outer diameters and inspect the entire surface. This is being done by six cameras moving around the rack taking pictures on altogether 20 positions, leaving a cycle time of some hundred milliseconds for image acquisition and processing for each pipette. Typical dimensions of a pipette point are an inner diameter of 0.5mm (tolerances 0050/0) and an outer diameter of 0.9mm (tolerances 0025 / -0025). According to the software algorithms programmed by Qualimatest defects are sorted out automatically and separated by defect type. In addition, the system delivers a statistical analysis on eight different parameters on defect control such as homogeneity in order to further adjust and improve the manufacturing process.

Such a system can only operate with a high-performance vision PC as its core element. Subsequently, Qualimatest thoroughly chose the right product after an intensive test phase, explains Arnaud Rollin, Software Developer at Qualimatest. “Our basic requirements were to have a compact, reliable industrial vision PC which easily fits into the control cabinet. Having the choice narrowed down to some five possible candidates we then made a benchmark amongst these products. Taking all relevant factors into account such as performance and speed, size, price, and additional options the Tattile M100 GigE Vision Controller came out as the best fit for this application. All six available GigE ports of the M100 are used in the Zubler machines. The integrated I/O provided by Tattile enables fast triggering of camera and lighting in real timethrough the connected FPGA which has the Zubler control signals for camera positioning on board.”

Arnaud Rollin is also very pleased about the additional features Tattile provides in the event more than six cameras are needed: “In this case Tattile offers an expansion chassis to integrate an external PCI-card in order to manage additional I/O or cameras.” Finally, the Qualimatest engineer is impressed by the robustness of the industrial vision controller provided by its supplier Tattile: “We do not spend a single thought on failure of the Tattile vision controllers as the failure risk of these robust vision PCs is practically zero.” This reliability is a prerequisite, since the Zubler machines normally run 24 hours, 7 days a week.

Qualimatest pipette inspection system controlled by Tattile M100 GigE Vision Controller; picture source: Qualimatest SA