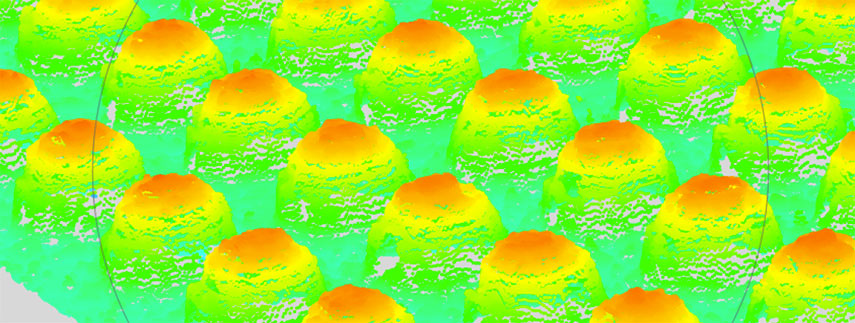

One BGA often consist of hundreds of single solder balls. To ensure the functionality of the electrical components, it is necessary that every single solder ball lead to a solid solder connection. The only way to ensure this is a one hundred percent inspection, where each solder ball must be measured three-dimensionally. Critical dimensions which need to be measured are for example the arrangement of the grid, the ball height or the ball coplanarity. Also, missing balls and defects of the substrate must be detected. With a one hundred percent control, it is possible to detect and sort out BGAs that do not meet the quality requirements. If defective BGAs are sorted out before the soldering process, significant costs can be saved.

The complete measurement task is very demanding. A large number of balls must be measured for various quality criteria in a very short time. To ensure a very high throughput, allowing for a one hundred percent inline inspection, the system must be able to test multiple BGAs in parallel.

The combination of the high resolution 2D color image and high 3D measurement accuracy with an extremely high acquisition speed makes the Chromasens 3DPIXA wave the perfect measuring device for this challenging 3D vision application. The following report presents technical details and achieved results for the 3D BGA inspection tasks employing Chromasens 3DPIXA wave cameras.